SPECIALTY CHEMICAL

Heat Exchanger Fabrication Specialist

SPECIALTY CHEMICAL INDUSTRY

BEST-IN CLASS HEAT EXCHANGER SOLUTIONS

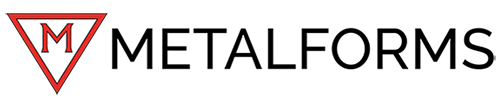

Since 1968, Metalforms has been a trusted leader in the design and fabrication of shell and tube heat exchangers, offering specialized solutions tailored to the unique demands of the specialty chemical industry. From corrosive and high-purity process streams to batch-reaction heating and cooling, thermal cycling, and stringent safety requirements, we help operators solve complex heat-transfer challenges with reliable, high-performance equipment.

Our dedicated 24/7 fabrication teams and ability to manage multiple projects simultaneously enable us to support all your heat exchanger needs—whether for new facilities, plant expansions, routine turnarounds, targeted modifications, or urgent emergency repairs.

Our in-house design engineers perform detailed thermal, vibrational, and mechanical evaluations to ensure each heat exchanger is precisely engineered to the unique processes and reactions in your facility. By optimizing for performance and durability, we help maintain efficiency, safety, and long-term reliability across your specialty chemical operations.

|

|

|

We Know Refining

REFINING & BIOFUELS PROCESSING PLANT HEAT EXCHANGER SPECIALISTS

-

Heat Exchanger FabricationWe manufacture a broad range of shell & tube heat exchangers for petrochemical plant owner operators—with available configurations and options to serve virtually any purpose.

All our heat exchangers are built to ASME, TEMA, and API standards as needed in addition to customer specifications. Example options include:

- Double Tubesheet

- Expansion Joints

- Floating & Fixed Head Options

- Insulation Jackets

- Lined & Unlined Flanges

- Multitube

- Parallel Units

- Parallel-Flow,

- Counter-Flow

- U-tube

- Parallel Units

- Expansion Joints

- Insulation Jackets

- Lined & Unlined Flanges

- With & Without Phase Change

-

Strip & Retube

Our strip & retube capabilities and expertise is available for all TEMA types of shell and tube heat exchangers as well as fin-fan type air cooled heat exchangers (ACHEs - also called air coolers.)

We have the unique ability to handle multiple strip and retube jobs simultaneously—and with our ability to perform work around the clock, 24/7, we can meet your most demanding project needs!

-

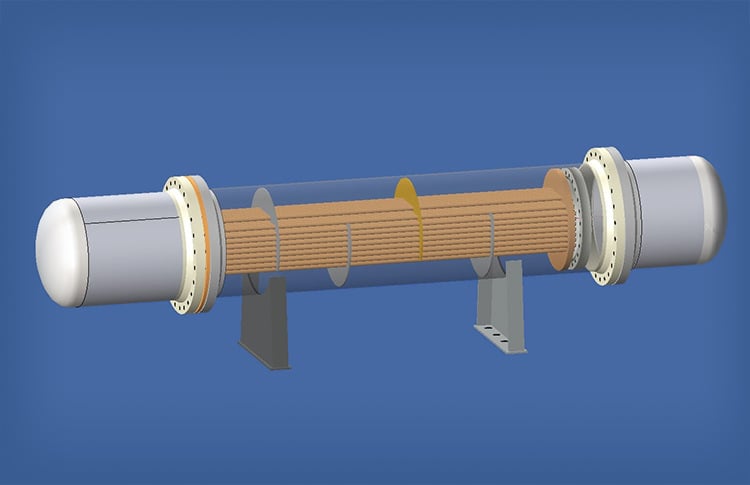

Heat Exchanger RepairWhen your heat exchangers arrive at our shop for repair, our expert teams rapidly inspect and diagnose your units for both common and highly complex issues. Prior to work commencing, all needed repairs—and options—are discussed with the customer. Common repairs include:

- Gasket surface repair

- Weld repairs

- Weld build-up & re-machining

- Replacement components

- Repairs to shell & channel

components - Coating & paint application

The most common types of weld repairs we perform are weld build-up repair of eroded and/or corroded areas, removal of cracks—and re-weld of those defects, and weld build-up for reclaiming gasket surfaces.

Any defects we find are removed by following the ASME Section IX qualified weld procedures.

-

Re-Rate & ModificationWe can re-rate, adjust, upgrade, or reconfigure your current shell and tube heat exchanger or ASME pressure vessel to suit new operatong conditions or to suit new applications at your ASU.

Rerating:

After a thorough evaluation of your unit, we'll discuss any needed modifications with you prior to beginning any work. If your unit already meets new requirements and/or once updates have been made, we'll provide all necessary documentation—to confirm the existing design will safely and efficiently perform to the new specifications, as required by owners and regulators alike.

Modifications

Whether or not re-rating is required, we can assist with virtually any shell & tube heat exchanger or ASME pressure vessel repair and/or alteration including design, configuration, options/features, or materials of construction.

All modified units will meet all applicable ASME, NBIC, TEMA, and API codes and standards.

-

Replacement PartsMetalforms manufactures replacement parts for both standard and emergency needs. With 24-7 engineering and fabrication teams, we can support your most urgent shell & tube heat exchanger parts and component needs including:

• Replacement bundles including u-tube, straight tube, & hairpin configurations

• Fixed & floating heads

• Replacement shells

• Bundle/shell combinations

• Replacement channels

•. Gaskets• Replacement channel covers

• Baffles

• Nozzles

• Insulation

• Expansion joints

• Various other miscellaneous parts

Learn more about our shell & tube heat exchanger components & parts services here.

-

BAHX Installation & MROOur sister company, Maddox Industrial Group (MIG)—also a TransTech company—delivers outstanding turnkey braised aluminum heat exchanger (BAHX) installation, preventative maintenance, & repair services, and changeouts to support optimal cryogenic processes for ASU owner/operators.

With four decades of experience, our seasoned teams have the experience and expertise to optimize temperature and pressure capabilities and maximize performance across the plant lifecycle.

MIG is one of the only companies in the U.S. to provide end-to-end field and shop maintenance, testing, and repairs of BAHX heat exchangers—and has earned a reputation for meeting quick response parameters in emergency repair settings.

Learn more about MIG's braised aluminum heat exchanger installation, maintenance, and repair services here.>

FREE Specialized Services Overview

Receive a Detailed Overview of All Our Services

- A Complete Services Overview

- Capabilities & Solutions

- Sample Projects

- Locations & Contacts

- More